In Brief: Metric Bolt Torque Chart – Class 8.8, Class 10.9, Class 12.9

These metric bolt torque charts show the ideal tightening torque for class 8.8, 10.9, and 12.9 bolts for both wet and dry tightening. The bolt’s class indicates its material strength, with higher numbers meaning higher tensile and yield strength. The classes are set by the International Standards Organisation or ISO.

The metric classes adhere to ISO standards, set by the International Standards Organisation, that apply across most industrialized nations.

The class indicates the material strength of the bolt.

The higher the class, the stronger the bolt. The most common metric bolt classes are Class 8.8, Class 10.9, and Class 12.9. Lower and higher classes exist, but do not see as much use.

For a rundown of the different grading systems and what they mean, check out this video from The Home Depot:

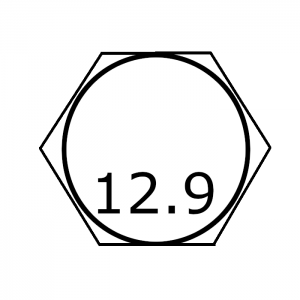

You can tell which bolt you are working with by the markings on the head.

Compare the bolts you have with the diagrams below, then refer to the appropriate chart to see the ideal tightening torque.

Metric Bolt Torque Chart

You must use the correct torque when tightening bolts.

If you properly torque the bolts, they will provide the maximum amount of clamping force under load. If you under torque the bolts, they can quickly come loose.

If you over-torque them, they are liable to break.

Refer to the charts below, which show the ideal tightening torque for each bolt grade for a variety of sizes.

Identify the class by the embossed number on the head, then find the size of your bolt in the chart. The ideal tightening torque can be found listed in two columns to the right.

The “wet” column indicates lubricated bolts, whereas the “dry” column indicated unlubricated bolts.

Metric Class 8.8 Bolt Torque Chart

Metric class 8.8 bolts are also known as structural grade bolts.

They are made of quenched and tempered medium carbon steel and can be plated with a variety of materials, most commonly zinc.

Class 8.8 bolts see common use in a wide range of industries.

Depending on size, they have a proof load of 580-600 MPa, minimum yield strength of 640-660 MPa, and a minimum tensile strength of 800-830 MPa. Class 8.8 bolts come in all sizes ranging up to 72 mm.

Table 1 – Ideal tightening torque for dry and wet metric class 8.8 bolts

| Size | Tightening Torque (Dry) / lb-ft | Tightening Torque (Wet) / lb-ft |

|---|---|---|

| M4 x 0.7 | 2.3 | 1.7 |

| M5 x 0.8 | 4.5 | 3.4 |

| M6 x 1 | 7.7 | 5.8 |

| M7 x 1 | 13 | 9.7 |

| M8 x 1.25 | 18.8 | 14.1 |

| M10 x 1.5 | 37.2 | 27.9 |

| M12 x 1.75 | 64.9 | 48.7 |

| M14 x 2 | 103.7 | 77.8 |

| M16 x 2 | 161 | 121 |

| M18 x 2.5 | 222 | 167 |

Metric Class 10.9 Bolt Torque Chart

Metric class 10.9 bolts see common use in the automotive industry.

They excel at bolting large parts, and many socket and countersunk buttons comply with the 10.9 grade.

They are generally made from carbon or boron alloy steel, quenched and tempered.

They have a proof load of 830 MPa, minimum yield strength of 940 MPa, and a minimum tensile strength of 1040 MPa. Class 10.9 bolts come in sizes ranging from 5 mm to 100 mm.

Table 2 – Ideal tightening torque for dry and wet metric class 10.9 bolts

| Size | Tightening Torque (Dry) / lb-ft | Tightening Torque (Wet) / lb-ft |

|---|---|---|

| M4 x 0.7 | 3.2 | 2.4 |

| M5 x 0.8 | 6.5 | 4.9 |

| M6 x 1 | 11.1 | 8.3 |

| M7 x 1 | 18.5 | 13.9 |

| M8 x 1.25 | 26.9 | 20.2 |

| M10 x 1.5 | 53.2 | 39.9 |

| M12 x 1.75 | 92.8 | 69.6 |

| M14 x 2 | 148.4 | 111.3 |

| M16 x 2 | 230 | 173 |

| M18 x 2.5 | 318 | 239 |

Metric Class 12.9 Bolt Torque Chart

Metric class 12.9 bolts are made from quenched and tempered alloy steel and see the most use in heavy-duty applications.

They are often used to secure engines and drives, alongside a host of other demanding applications.

They have a proof load of 970 MPa, minimum yield strength of 1100 MPa, and a minimum tensile strength of 1220 MPa. Class 12.9 bolts come in sizes ranging from 1.6 mm to 100 mm.

Table 3 – Ideal tightening torque for dry and wet metric class 12.9 bolts

| Size | Tightening Torque (Dry) / lb-ft | Tightening Torque (Wet) / lb-ft |

|---|---|---|

| M4 x 0.7 | 3.8 | 2.8 |

| M5 x 0.8 | 7.6 | 5.7 |

| M6 x 1 | 13 | 9.7 |

| M7 x 1 | 21.7 | 16.3 |

| M8 x 1.25 | 31.4 | 23.6 |

| M10 x 1.5 | 62.2 | 46.7 |

| M12 x 1.75 | 108.5 | 81.4 |

| M14 x 2 | 173.4 | 130 |

| M16 x 2 | 269 | 202 |

| M18 x 2.5 | 372 | 279 |

Summary

We hope these metric bolt torque charts have helped you discover the correct tightening torque for the bolts you use.

If you might need to look up the ideal tightening torque for metric class bolts again, why not bookmark this page so that you can refer to it more easily in the future?